Post-processing

Medical Device Textile Solutions

Implantable medical textiles undergo a rigorous finishing process before becoming viable medical device components used in stents, hernia mesh, or synthetic ligaments.

At Secant, we employ a variety of finishing techniques such as scouring, heat treatment, coating, and welding to clean, shape, stabilize, and tune specific properties of fabrics (e.g., thickness, water permeability) to ensure that materials maintain functional integrity in the human body.

Preparing advanced medical textiles for implantation

Take advantage of Secant’s suite of post-processing services to ensure that a final implantable textile component for a cardiovascular, general surgery, orthopedic, or neurovascular medical device arrives exactly as you need it so it can perform exactly as expected.

Working directly with a supplier that can add custom finishing techniques and finalization to braided, knitted, or woven textile components keeps projects on time, on budget, and on the cutting edge of innovation.

Techniques:

- Calendering

- Coating

- Crimping

- Heat treatment

- Laser cutting (2D and 3D)

- Post-finishing and final packaging

- Scouring

- Stitching

- Ultrasonic welding, sealing, and sewing

Explore Post-processing Techniques

Ensure textiles are ready to perform in a medical device by finalizing the structure with a variety of post-processing techniques.

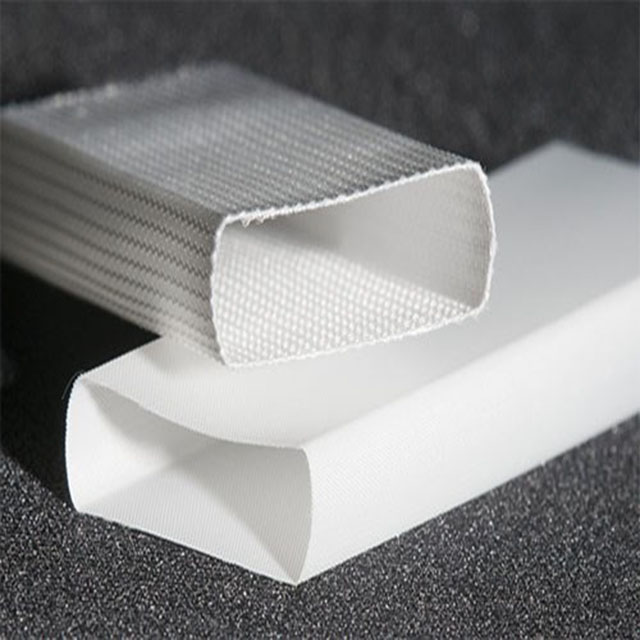

Calendering

Achieve a lower thickness profile for a fabric.

Method

- Passing fabric through two heavy rollers, which can be heated

Coating

Create an impermeable or less permeable structure, provide stretch and recovery, modify a surface to promote tissue in-growth and healing, or increase or reduce surface friction.

Methods

- Casting

- Dip coating

- In-line coating

- Spray coating

Materials

- Poly(glycerol sebacate) (PGS)

- Polyurethane

- Silicone-based polymers

Crimping

Attach an atraumatic needle to a textile component (e.g., braided tethers, sutures, microporous knit tape) utilizing a needle crimper to ease penetration, close wounds, or create a sewing thread.

Heat treatment (polymers & metals)

Shape 2D constructs over 3D mandrels or tools, or between two heated plates, to achieve geometries that cannot be accomplished by braiding, knitting, or weaving.

Methods (Hot air and inert)

- Thermoforming

- Heat-pressing

Benefits

- Dimensional stability

- Shape memory

- Transformation from 2D to 3D geometry

- Uniform visual appearance

- Minimal wrinkles

- Consistency

Laser cutting (2D & 3D)

Laser cut braided, knit, and woven fabrics to a specific size-shape suitable for end application

Methods

- 2D Laser-cutting (flat)

- 3D Laser-cutting (tubular, rotary system)

Post-finishing & final packaging

Methods

- Visual inspection

- Dimensional testing

- Length and width, angle, construct density

- Destructive functional testing

- Suture retention, water permeability, compression, probe burst, ball burst, etc.

Final packaging for product protection and shipping

Methods

- Standard

- Vacuum sealing

Scouring

Remove spin finish/sizing applied during yarn production, warping, or for general cleaning of a textile component.

Methods (solvent-based and aqueous)

- Tumble wash (DI-water based)

- Ultrasonic cleaning (DI-water or solvent-based)

- IPA soak

- Hot DI-water bath

Stitching

Secure two or more components together or form loops or layers.

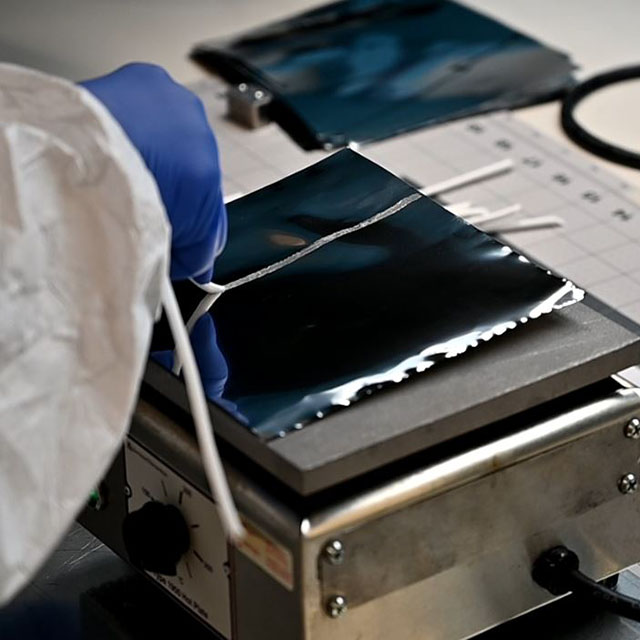

Ultrasonic welding, sealing, & sewing

Cut and create a welded/sealed edge, melt and harden a textile, or create a weld between two edges/components.

Method

- High-frequency ultrasonic acoustic vibrations

Start your medical device project today.

Contact us to learn more or explore resources on medical device textiles.