Neurovascular

Medical Device Textile Solutions

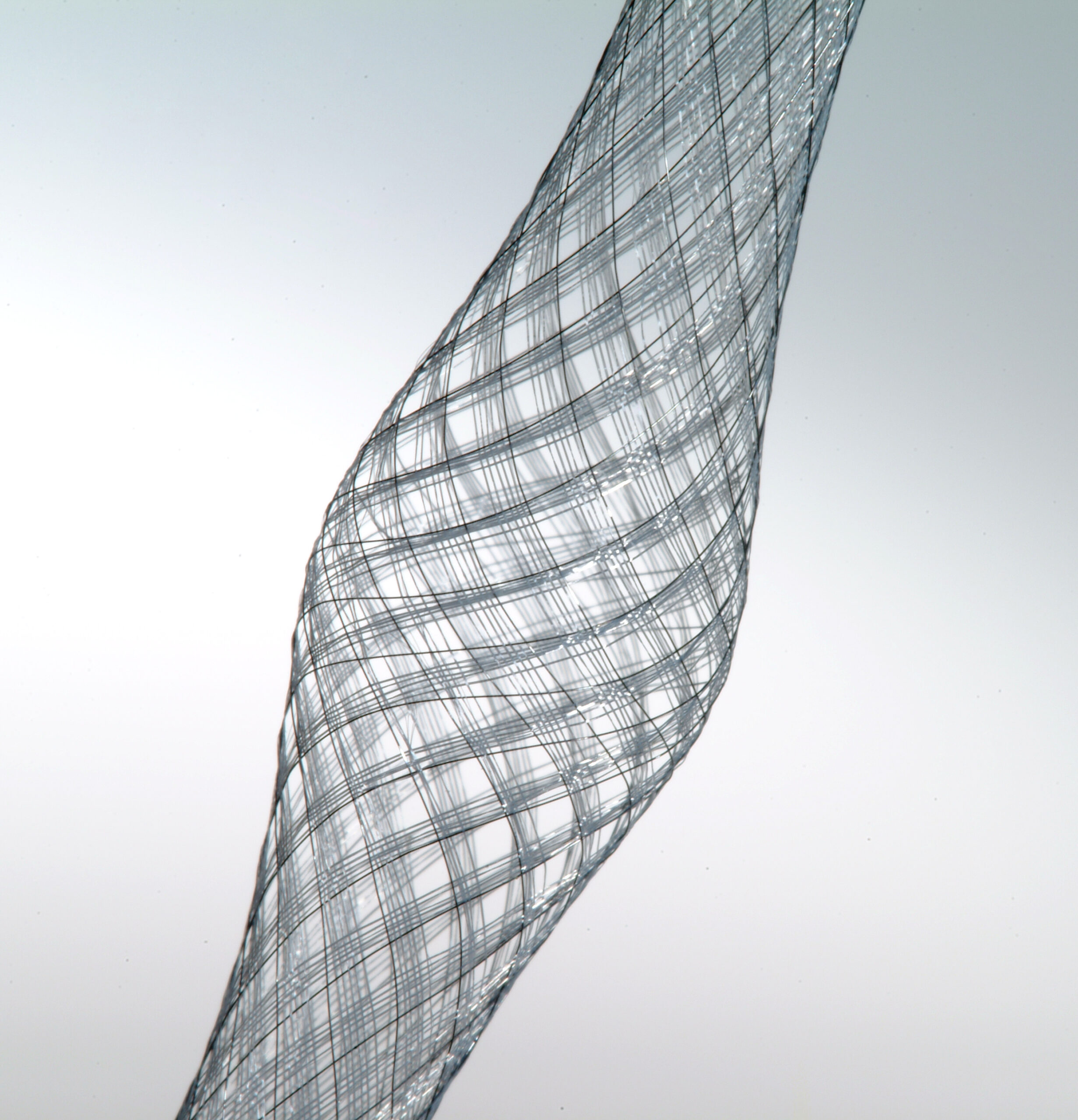

Combine advanced materials with biomedical textile forming technologies to enable minimally invasive expansion and compaction of critical neurovascular devices for aneurysm repair and stroke prevention and treatment.

The first step in developing a neurovascular device is identifying the most appropriate textile material to utilize. It’s a challenge Secant Group tackles immediately with every client – whether you’re a startup or global manufacturer.

Textiles for neurovascular devices can be applied in the following ways:

- As flexible structures for diverting blood flow, retrieving blood clots, or preventing or reducing plaque debris

A solutions-focused approach

With access to proactively built and readily available fabric samples, our device engineers can shorten lead times, limit development costs, and deliver a prototype in just a few weeks. In turn, you gain more customization and fabric modification throughout the product development process to meet new and emerging market needs.

Structures

- Clot retrieval devices

- Coils

- Embolic filtration devices

- High-density, shape memory alloy textile structures

Challenges Textiles Solve

- 3D dimensionality

- Compactibility

- Conformability

- Covering/protection (e.g., cushioning)

- Elasticity

- Flexibility

- High density

- High-surface area

- Longitudinal elongation

- Low profile

- Permeability

- Porosity

- Radial expansion

- Radiopacity

- Retrieval

- Sealing

- Shape memory

- Stretch

- Suturability

- Thickness

- Thinness

- Tissue in-growth

Explore Neurovascular Textile Solutions

Whether you’re creating a new device or enhancing a predicate device, manufacturers can count on Secant Group’s broad portfolio of advanced textile solutions and services to deliver high quality and specificity for neurovascular devices.

Neurovascular Aneurysm Repair

- Flow diverter components

- Intrasaccular flow disruption components

Ischemic Stroke Prevention & Treatment

- Clot retrieval thrombectomy components

- Embolic protection filter components

Materials

- Cobalt-chromium

- Nitinol

- Platinum

- Specialty alloys

Medical Textile-forming Technologies

-

Braiding: Providing unrivaled variability of physical and mechanical properties, braided textiles offer controlled porosity, flexibility, high radial expansion, and strength.

-

Knitting: Lightweight, highly conformable, and able to provide bulk, knit textiles enable versatile geometric structures with controlled elasticity and thickness, consistent pore size and shape, and elongation.

-

Weaving: Offering the most design flexibility of all textile-forming technologies, woven textiles deliver dimensional stability, low porosity, and strength.

Video Resources

Start your neurovascular device project today.

Contact us to learn more or explore resources on medical device textiles.